FULL FORM: PREDICTIVE MAINTENANCE

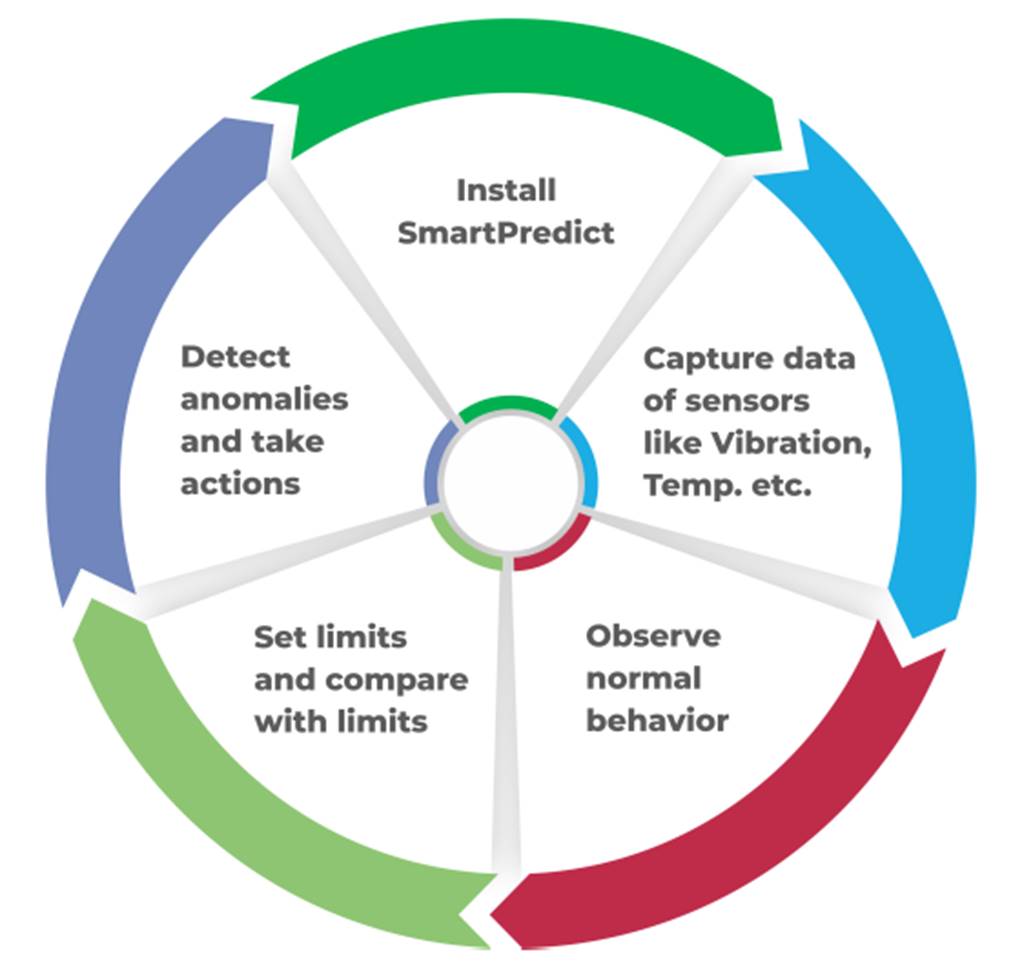

GRAPHICAL REPRESENTATION:

MEANING: Data from Sensors (internal & external) installed on any type of machine is used to detect symptoms, and PREDICT which problems can occur in future. Action is then initiated to ‘nip the problem in the bud’

The entire process of data collection, analysis & instructions for action is automatic and free from human dependence. It is therefore extremely reliable and works 24×7.

TYPES of PdM ACTIONS: There are THREE types of actions.

ADVANTAGE OVER TPM:

OPTIONS for Non-CNC Machines like Forging Presses, Die Casting, De-Coiling, Plastic Injection, etc: PdM can be installed on ANY type of machine, even manually operated. We need to understand basic working of machine and then select and install suitable sensors.

Payback Period (ROI) : 6-10 Months

CONCLUSION: PdM is an absolutely essential Industry 4.0 Technology that will drastically reduce breakdown downtime of machines & result in HUGE SAVINGS :