GRAPHICAL REPRESENTATION:

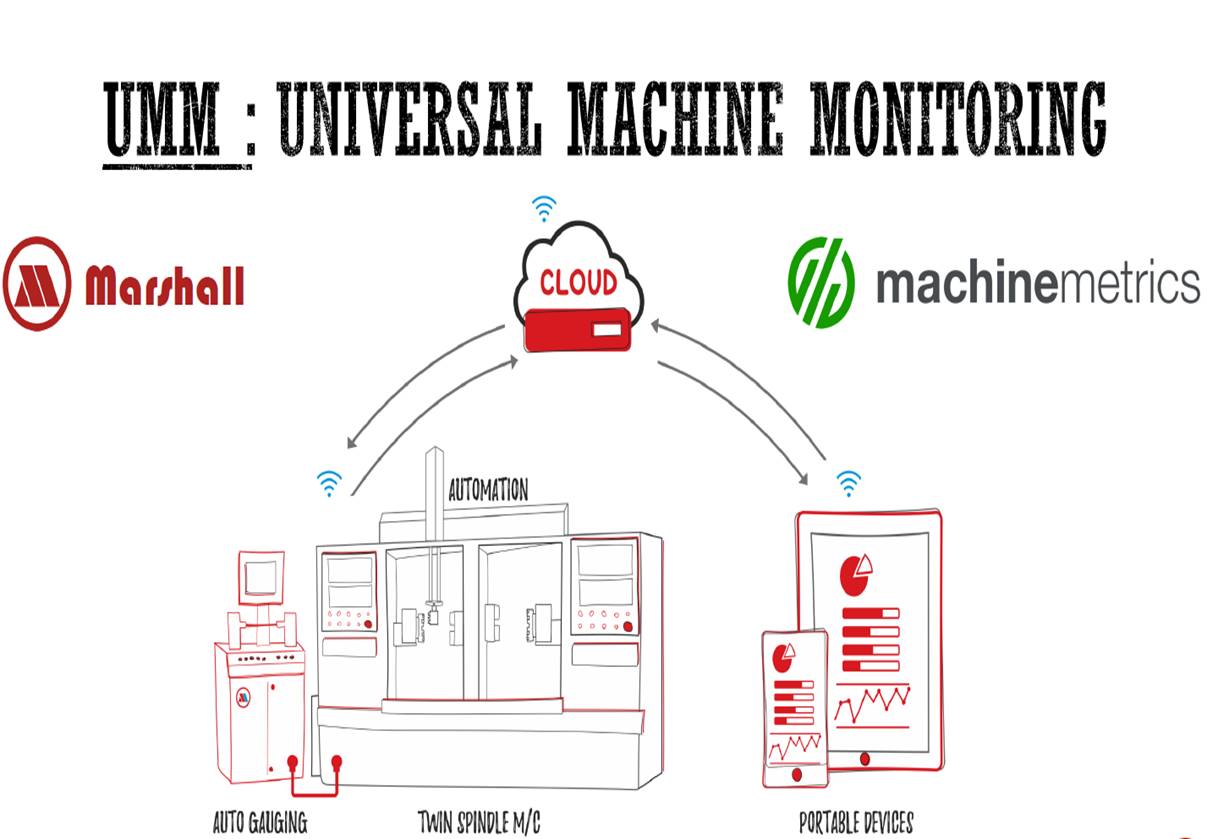

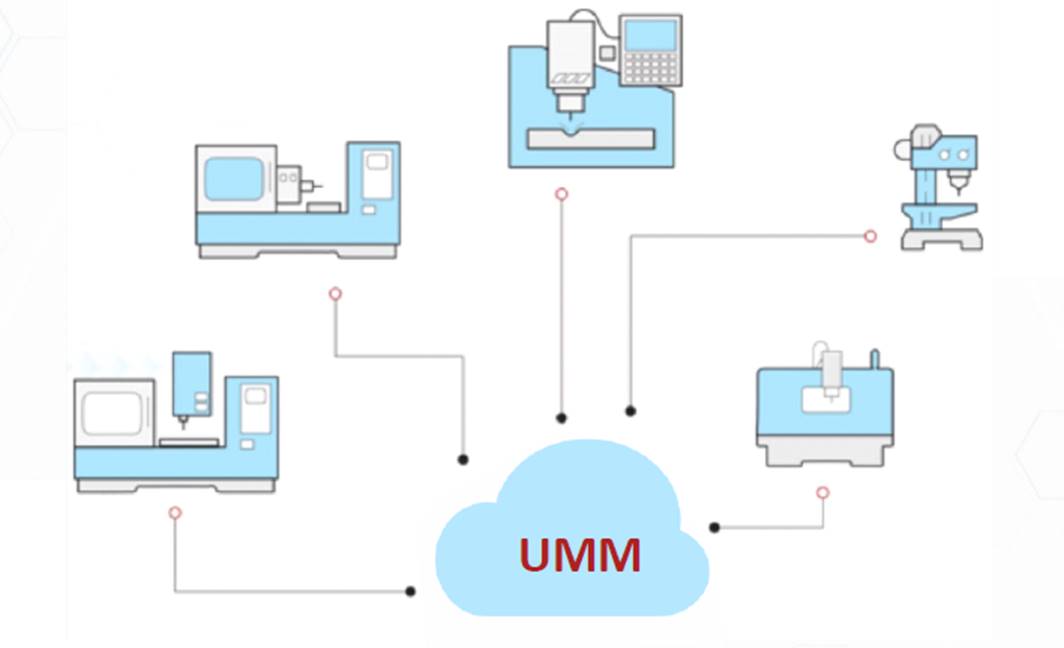

MEANING: UMM is the monitoring of the working of all types of machines DIGITALLY, with minimum human intervention, 24×7. There are 3 aspects to UMM :

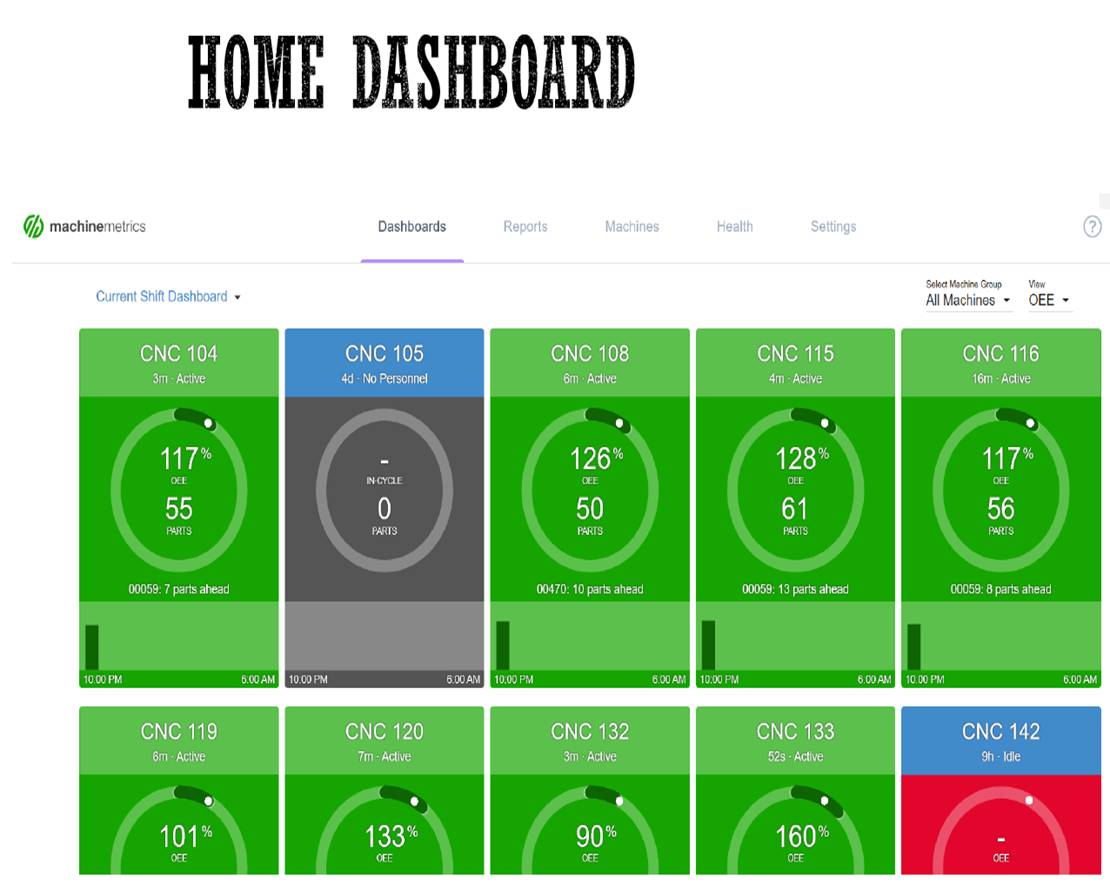

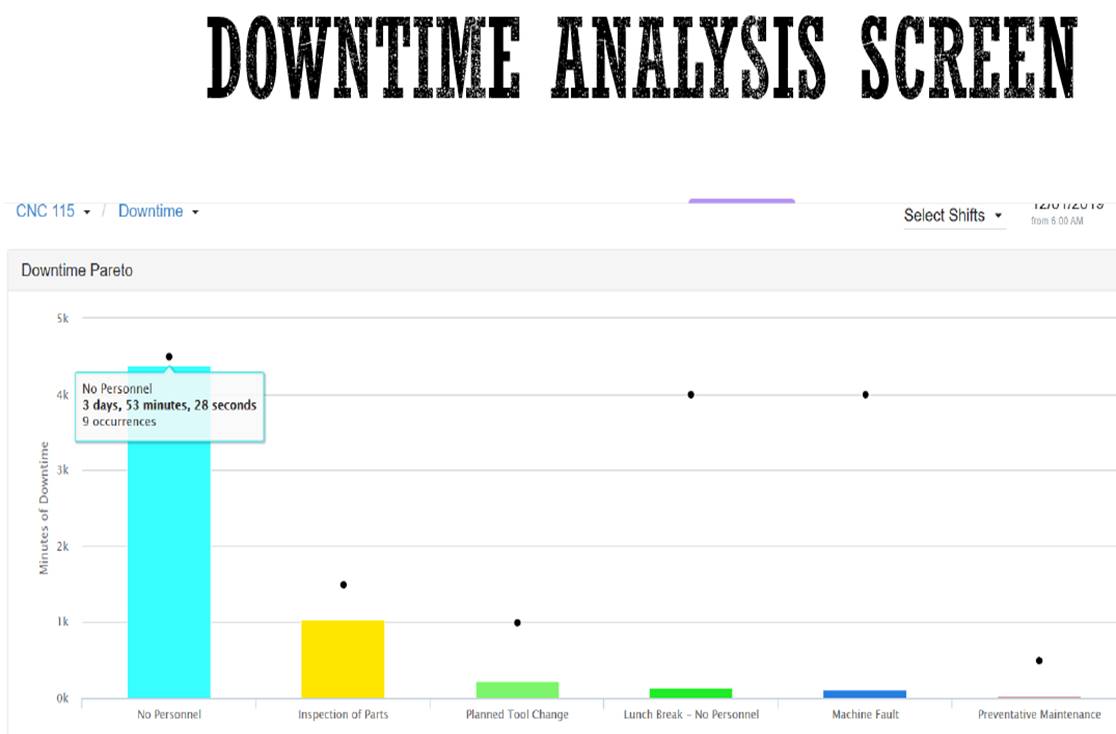

REPORT EXAMPLES:

BONUS: ALERTS are received by designated people based on thresholds or limits set by Managers. For Example, A limit of 10 minutes will set of ALERT to Supervisor if any machine does not start working after more than 10 minutes after shift change.

RESULTS: The results are generally like these.

It is as if for FIVE machines that you have of any type, SIXTH has been added FREE of cost, with no extra space & no operator!!

OPTIONS for Non-CNC Machines like Forging Presses, Die Casting, De-Coiling, Plastic Injection, etc: UMM is UNIVERSAL and hence can be used with ANY type of machine, even manually operated.

Payback Period (ROI) : 3-5 Months

CONCLUSION: UMM is an absolutely essential Industry 4.0 Technology that will reduce downtime of machines & increase OEE by 15-25% resulting in HUGE JUMP in PROFITS & COMPETITIVENESS!!