FULL FORM: Closed Loop Auto-Corrected Production

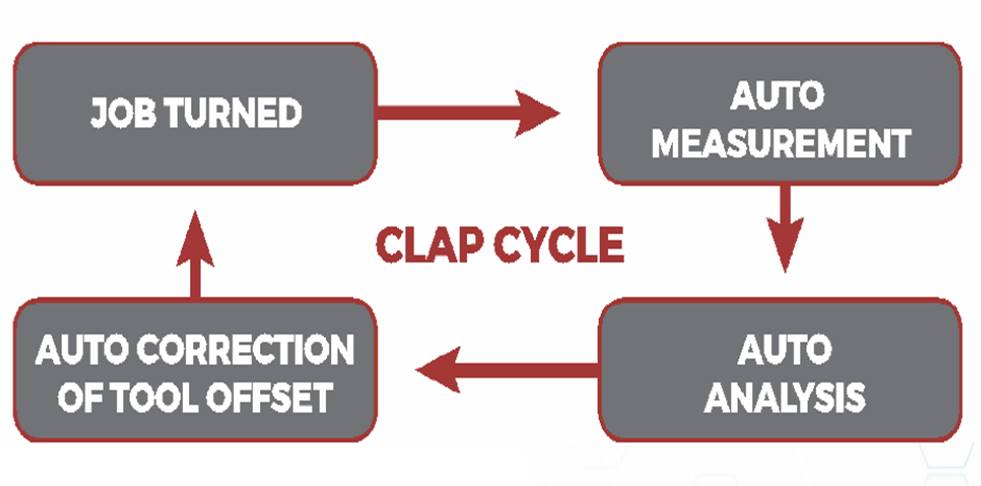

GRAPHICAL REPRESENTATION:

MEANING: Human errors like 1. Measurement Error 2. Judgement Error 3. Correction Input Error are eliminated as a Gauging Station (called SmartCorrect Auto Measures (with touch probes, air, vision or laser), Auto Analyses the Measurements (with Micro-processor) and Auto Corrects Tool offset in CNC machine through direct wired connection.

SmartCorrect GAUGING STATIONS:

RESULTS:

OPTIONS for VMC, HMC, Gear Hobbing, & Non-CNC Machines like Forging Presses, Die Casting, etc: SmartAlert Gauging Stations that ALERT Operators & Supervisors (through SMS) and can be programmed to stop machine if X number of defectives produced in succession or Y in an hour.

ROI: 6-10 months.

CONCLUSION: CLAP is an absolutely essential Industry 4.0 Technology that will eliminate dependence on skilled Operators & Quality Inspectors, SAVE huge amount of Rejection/Rework and delight your customer!