ALLOY WHEEL CELL

January 16, 2019

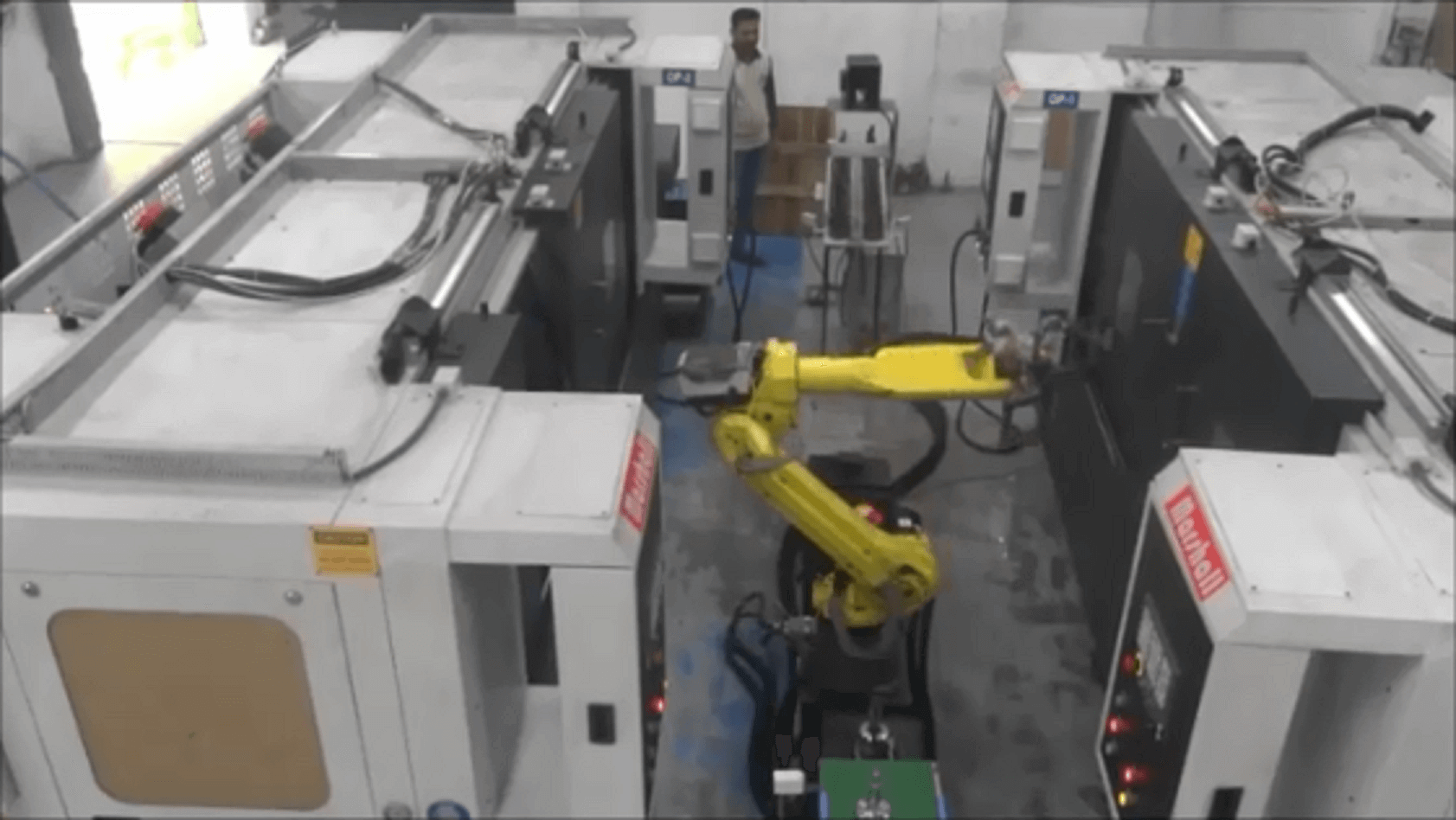

ROBOTURN CELL FOR 2 WHEELER SPROCKET

January 16, 2019REAR AXLE CELL

This is a complete automated solution for 3 wheeler rear axles. Some of the salient features of this cell are:- ·

- No centering facing required as centering is done on the machine itself ·

- Live turrets on both sides ( Special BMT type) for drilling and centering operations ·

- Complete turning of stem in the first setup ·

- Complete Flange turning and drilling in the second setup ·

- Linear Scales to ensure highest accuracy while machining ·

- Camera for orientation of the job and proper butting ·

- High pressure coolant for chip breaking and increase tool life ·

- Sister tools for un interrupted longer production ·

- Clampsys to protect against blunt and broken inserts ·

- Marshall proprietary smart screens for easy operation ·

- Robot for loading unloading

This is a two setup solution for a job which was being done in 5 setups previously. It saves a lot of space and reduces the floor to floor time. This is the ideal solution for such a component and with a robot we can easily achieve an OEE greater than 90%.

| SPECIFICATIONS | |

| CAPACITY | |

| Swing Over Carriage Cover (mm) | 360 |

| Maximum Turning Dia. (mm) | 260/320 |

| Maximum Turning Length (mm) | 350 |

| with Tailstock | |

| MAIN SPINDLE | |

| Spindle Nose (Standard) | A2-6 |

| Front Bearing Bore (mm) | 100 |

| Maximum Bar Capacity (Std.) (mm) | 52 |

| SPINDLE DRIVE | |

| Spindle Motor rated power (KW) | 11/15 |

| Inf. Variable speed range (rpm) | 100-3200 |

| RAPID TRAVERSE | |

| STANDARD | |

| X-axis (m/min.) | 24 |

| Z-axis (m/min.) | 24 |

| TOOL TURRET | |

| No.of Stations (Std.) | 8 |

| Tool of Cross Section | 25*25 |

| Max. Boring Bar Dia. | 40 |

| POSITIONING REPEATABILITY | |

| X-axis (m/min.) | + 1.5 Microns |

| Z-axis (m/min.) | + 2 Microns |

| CNC Controls:SIEMENS 828D(SL)/ FANUC 0i mate TD Weight (approx.) (Kg) | 6000 |