‘Closing the loop’ means the output of a system feeds back to directly adjust the performance of the system. For example, a furnace & a thermostat work together in a closed loop to control room temperature.

Imagine if the temperature readings had to be taken periodically by a person, who would then take the decision of reducing the furnace flame, and would keep repeating this task all day: This would be an example of an open loop system and it would be a very expensive, inefficient and potentially disastrous way of managing room temperature.

Yet most of the world operates in ‘Open Loop Mode’ with heavy dependence on humans; from Traffic Management to Assembly Operations, to running of CNC Machines.

I firmly believe that India can leapfrog most of the countries of the world and become a leader in ‘Closed Loop’ functioning, and the Indian manufacturing sector can lead the way.

CLOSED LOOP MANUFACTURING PRINCIPLE # 1: PREVENTION

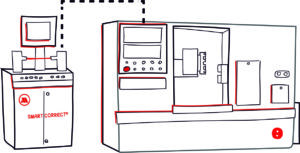

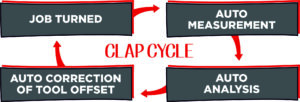

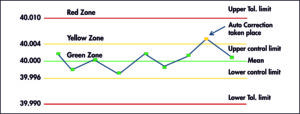

AUTO-GAUGING OF MACHINED JOBS & AUTO-CORRECTION OF CNC MACHINES. This ensures that near zero defect manufacturing can be done without relying on skilled operators & inspectors. In Traditional machine shops THREE skills are required in CNC machine operators, i.e. measurement skill, analytical skill & offset correction input skill. Operator can make errors in all three ‘skills’ and hence there is a need for line inspectors & pre-dispatch inspectors, who themselves can make errors, thereby allowing defective parts to reach customers. Closed Loop Auto-corrected Production (CLAP) ensures that defective parts are PREVENTED from being produced at all.

CLOSED LOOP MANUFACTURING PRINCIPLE # 2: ACTION

• In case some defective does get produced, designated persons receive information with ‘system based insights’ i.e. WHY was the defective produced?

• Record is automatically maintained of actions taken, in response to the information & insights, So that ‘Information + Insights + Actions become ‘Wisdom’ residing in the system and available to all within the organization.

CONCLUSION: When technology based systems will be used to ‘Close the Loop’ in factories, hospitals, farms, construction & in governments too, there will be a massive jump in efficiency (cost reduction & quality improvement) which will make India a prosperous country in a few years.

JAI HIND.