WHY

Manufacturing needs

TRANSFORMATION TODAY?

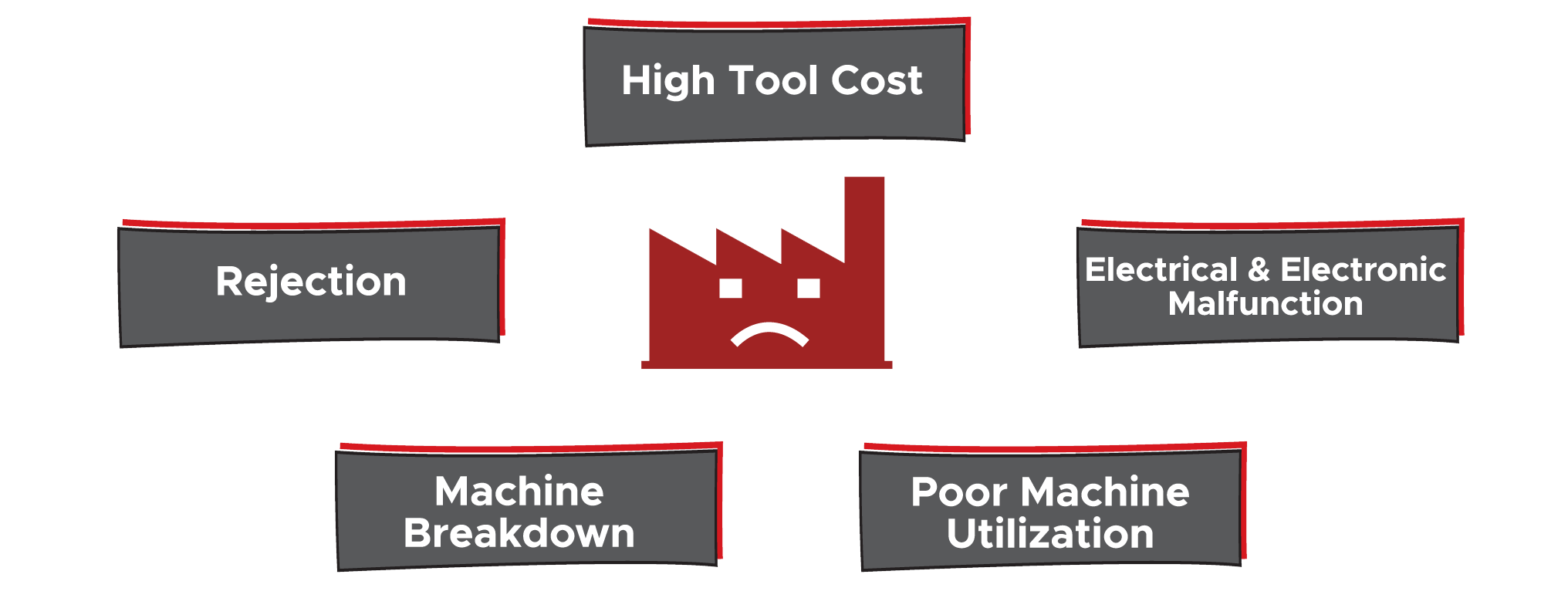

Problems of Manufacturing Sector

#1 PROFITS UNDER PRESSURE

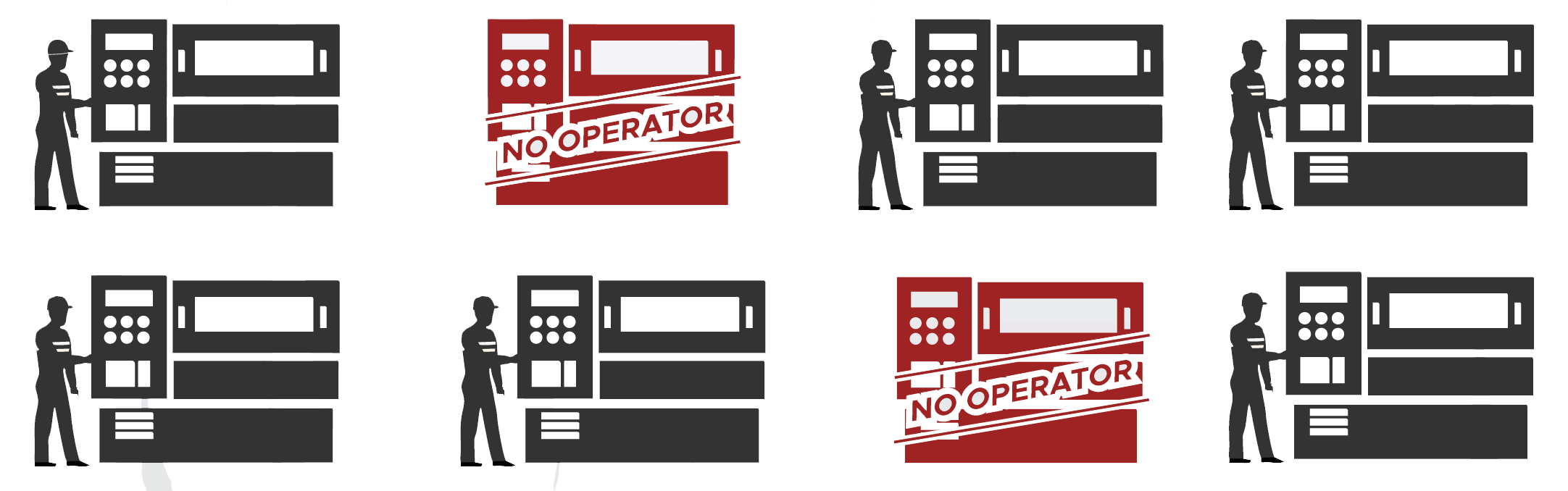

#2 SHORTAGE OF MACHINE OPERATORS

#3 Sub-Optimal Operation of Machine Shops

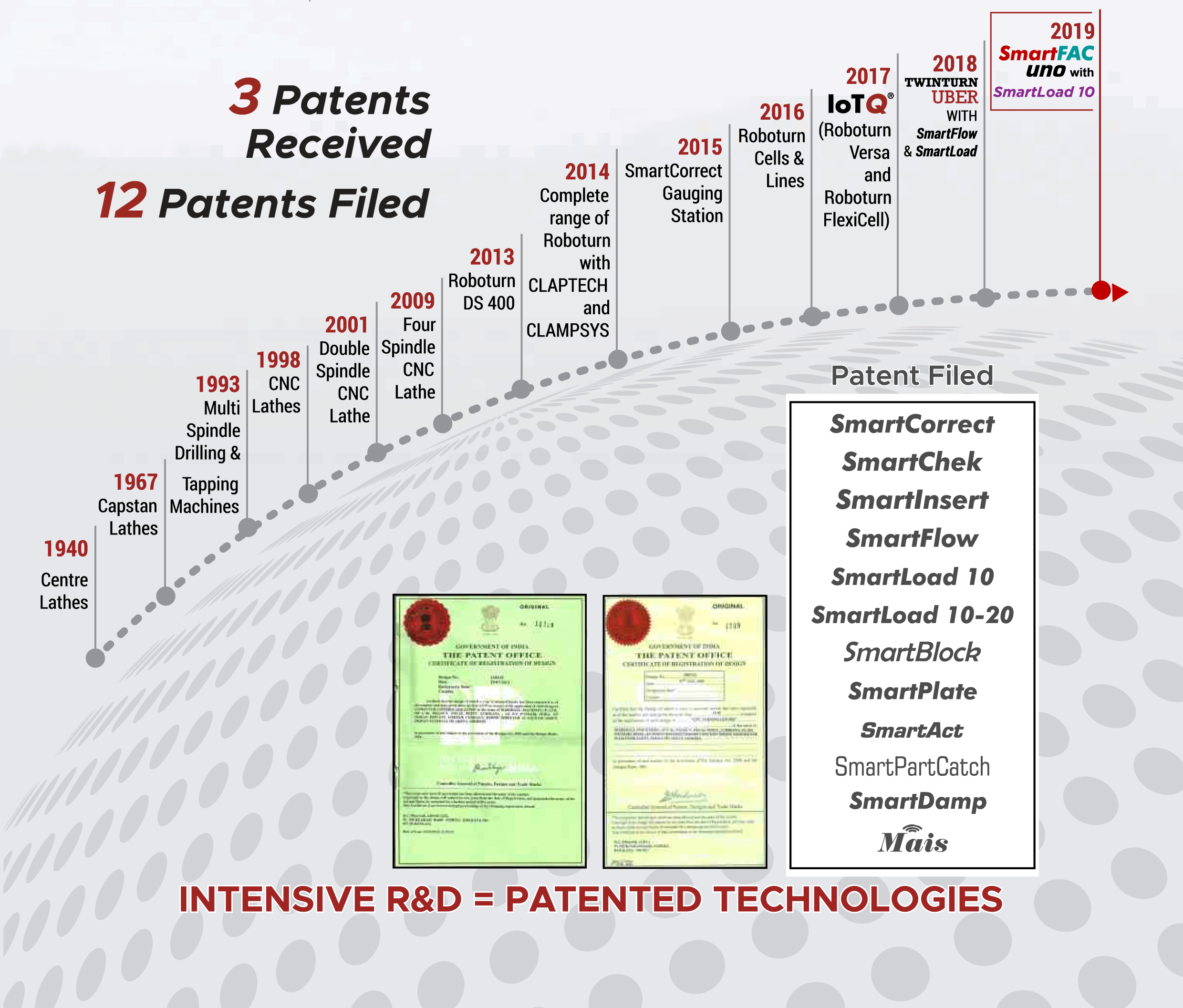

HOW

Marshall

has DEVELOPED SOLUTIONS

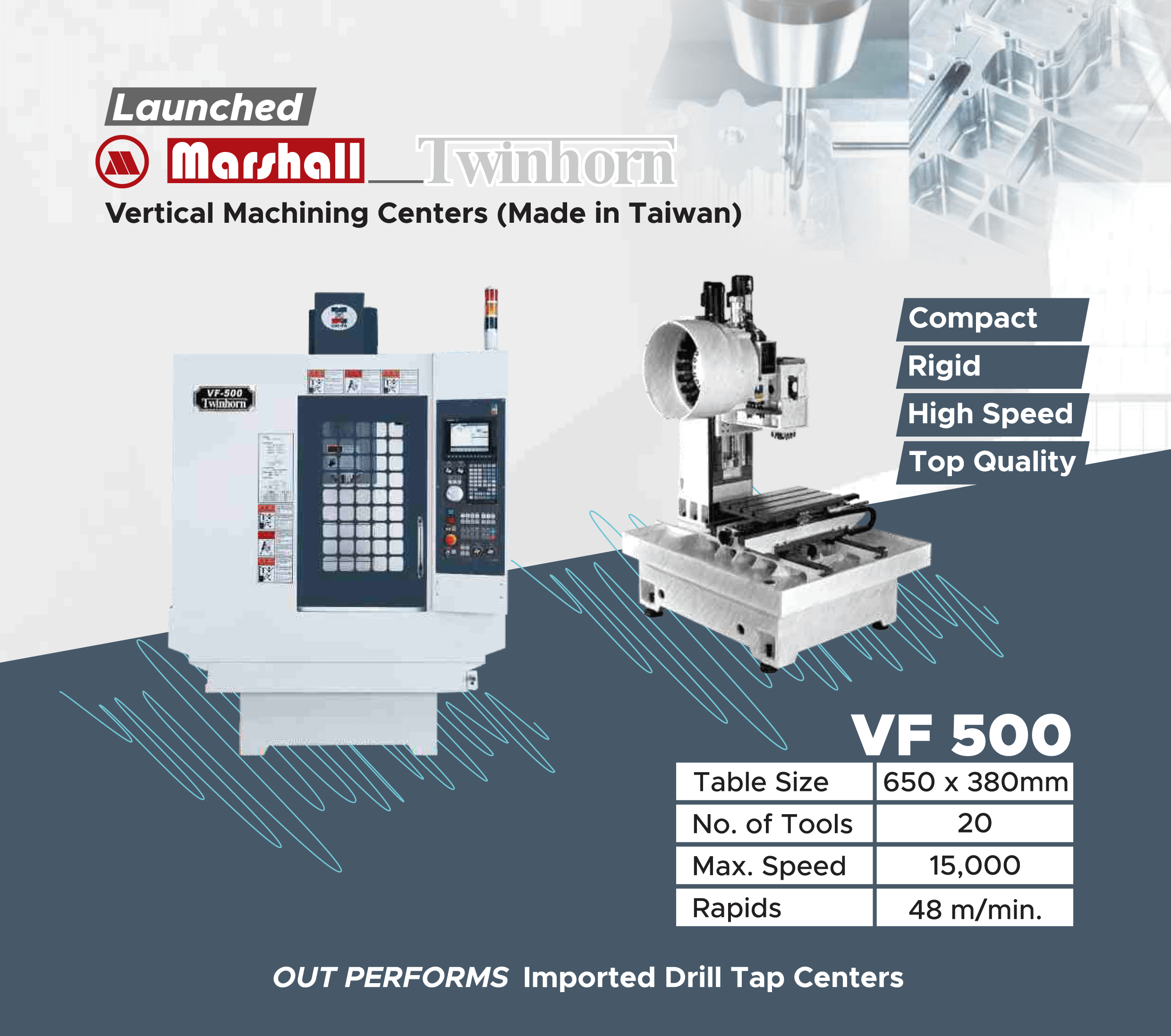

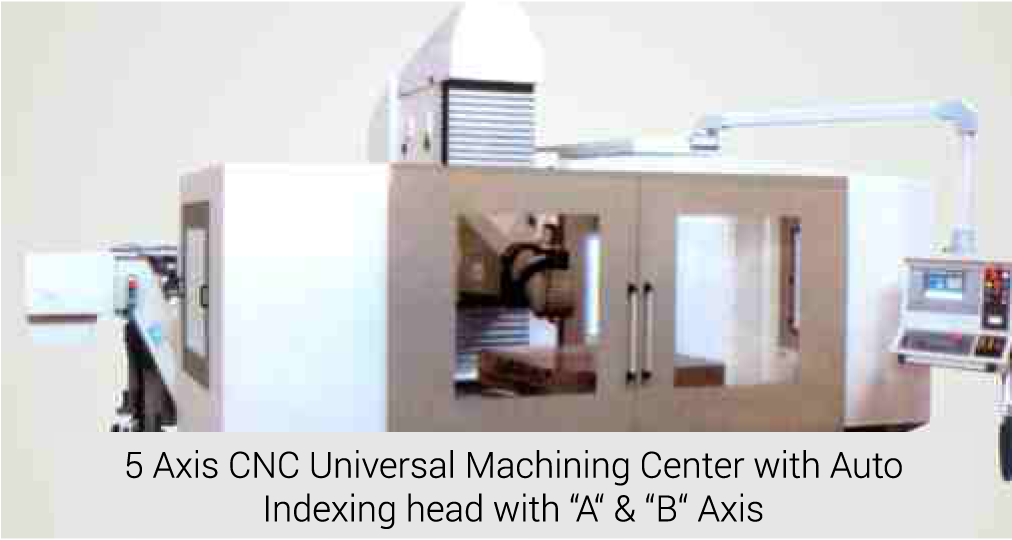

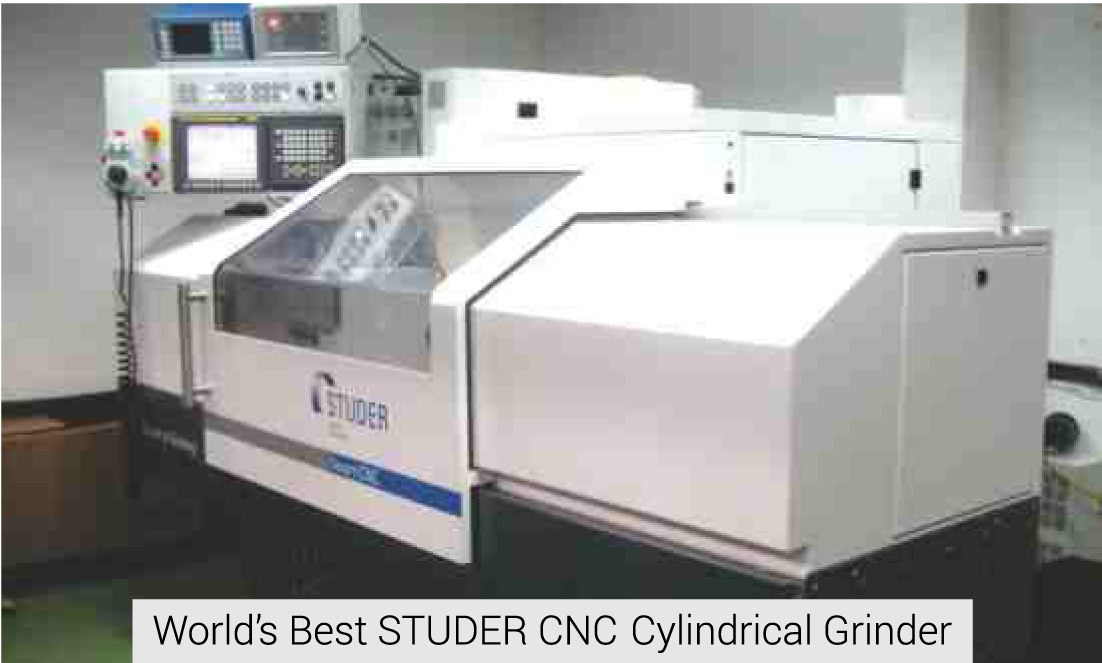

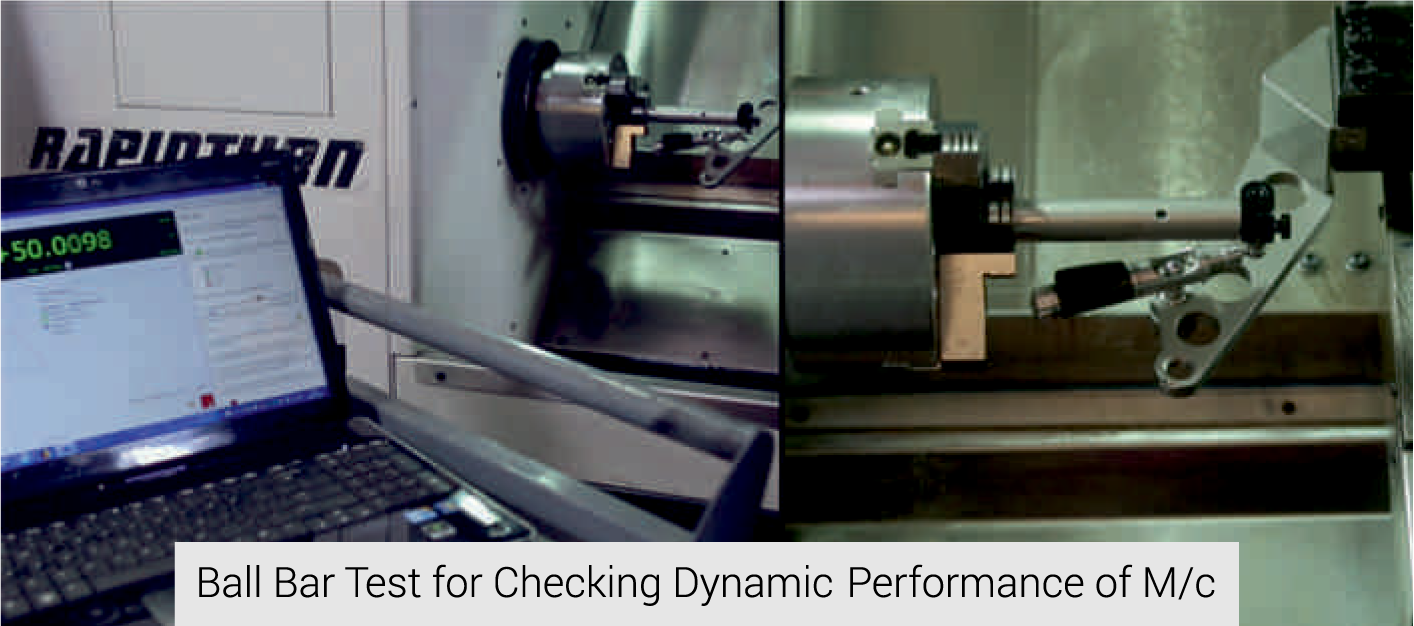

Our World class Infrastructure

WHAT

are the

SOLUTIONS

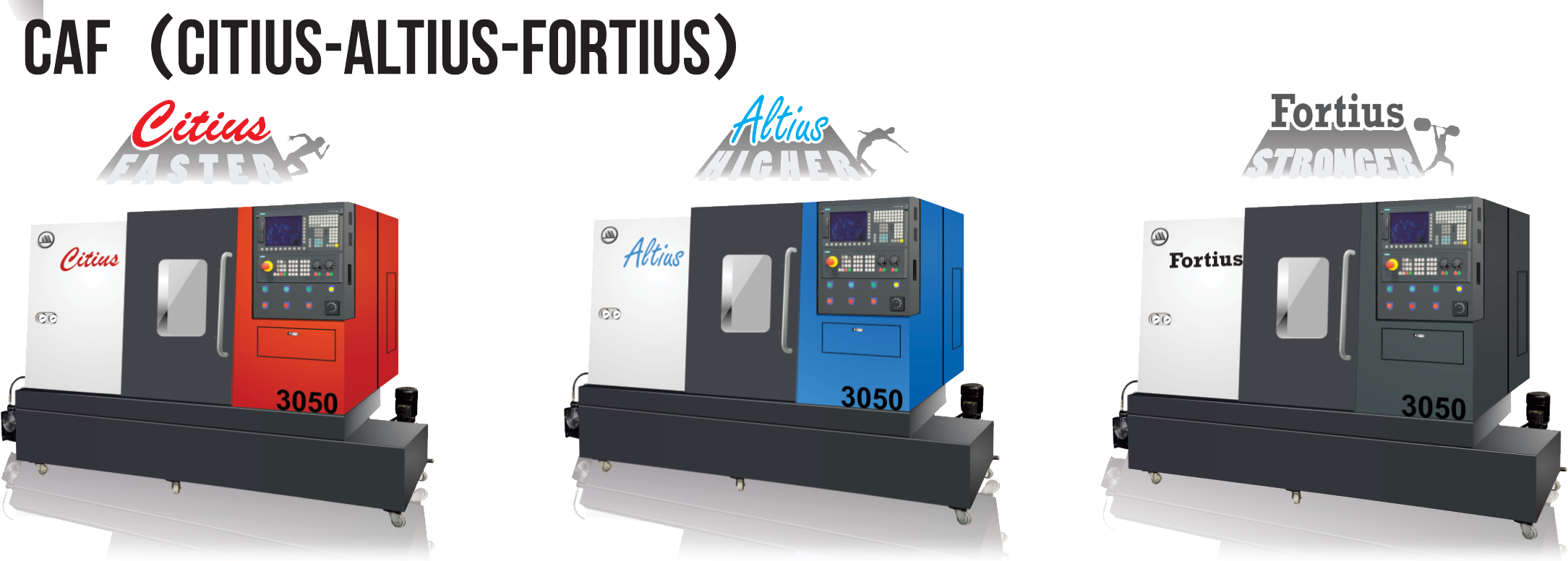

Super-Optimized Machines

CAF (CITIUS-ALTIUS-FORTIUS)

UNO

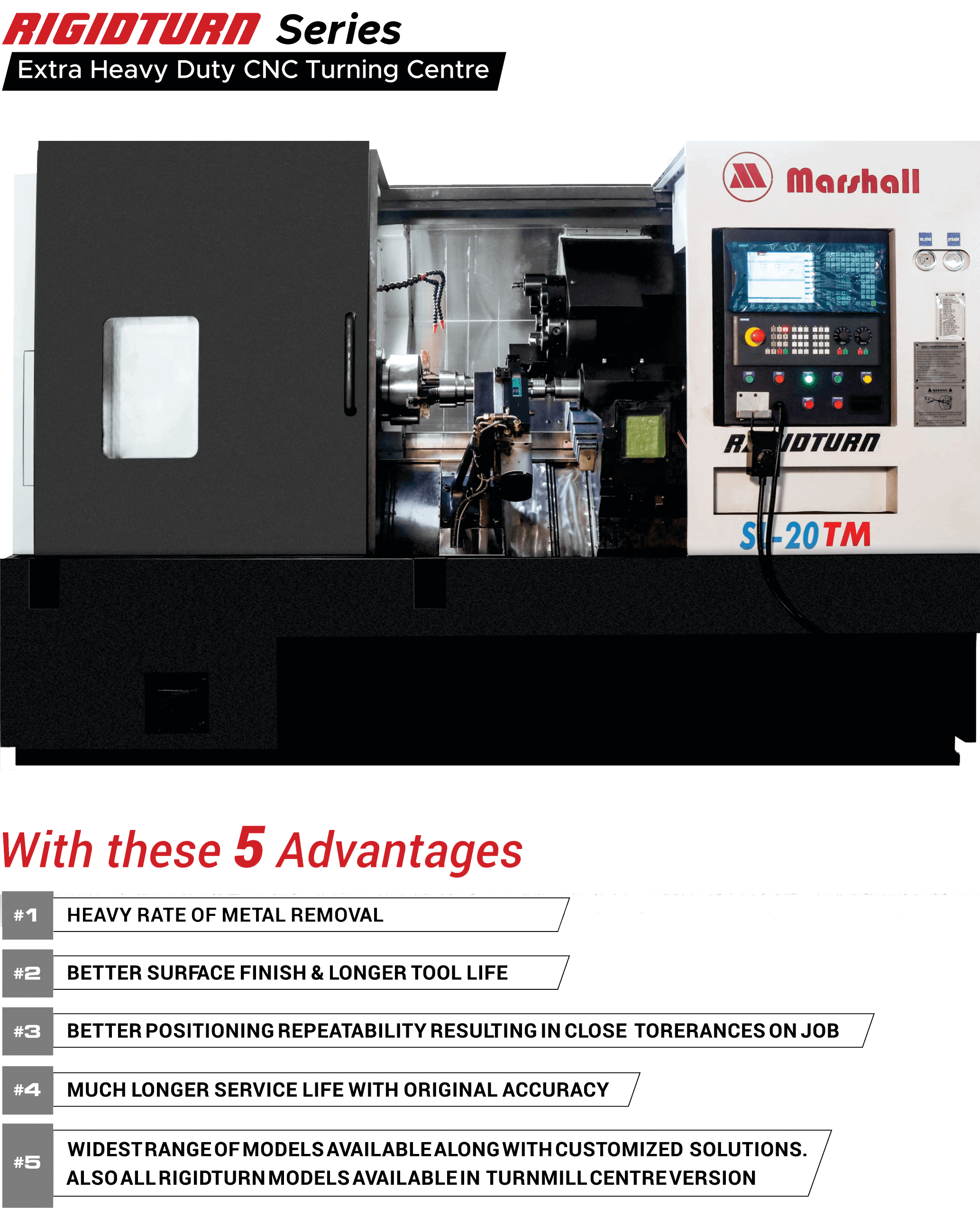

RIGIDTURN Series

TMH Series TURNMILLS

DOUBLE SPINDLE

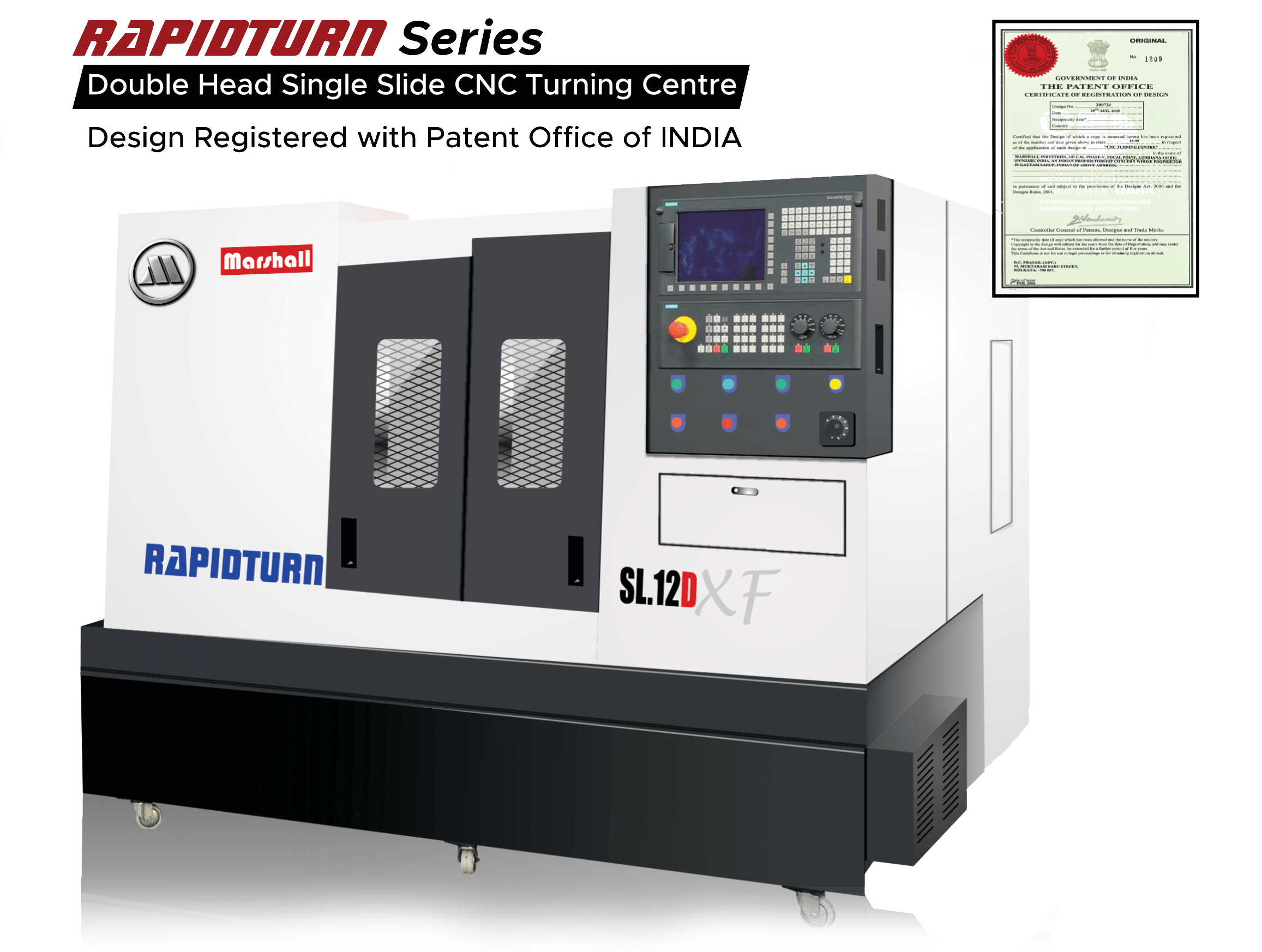

RAPIDTURN Series

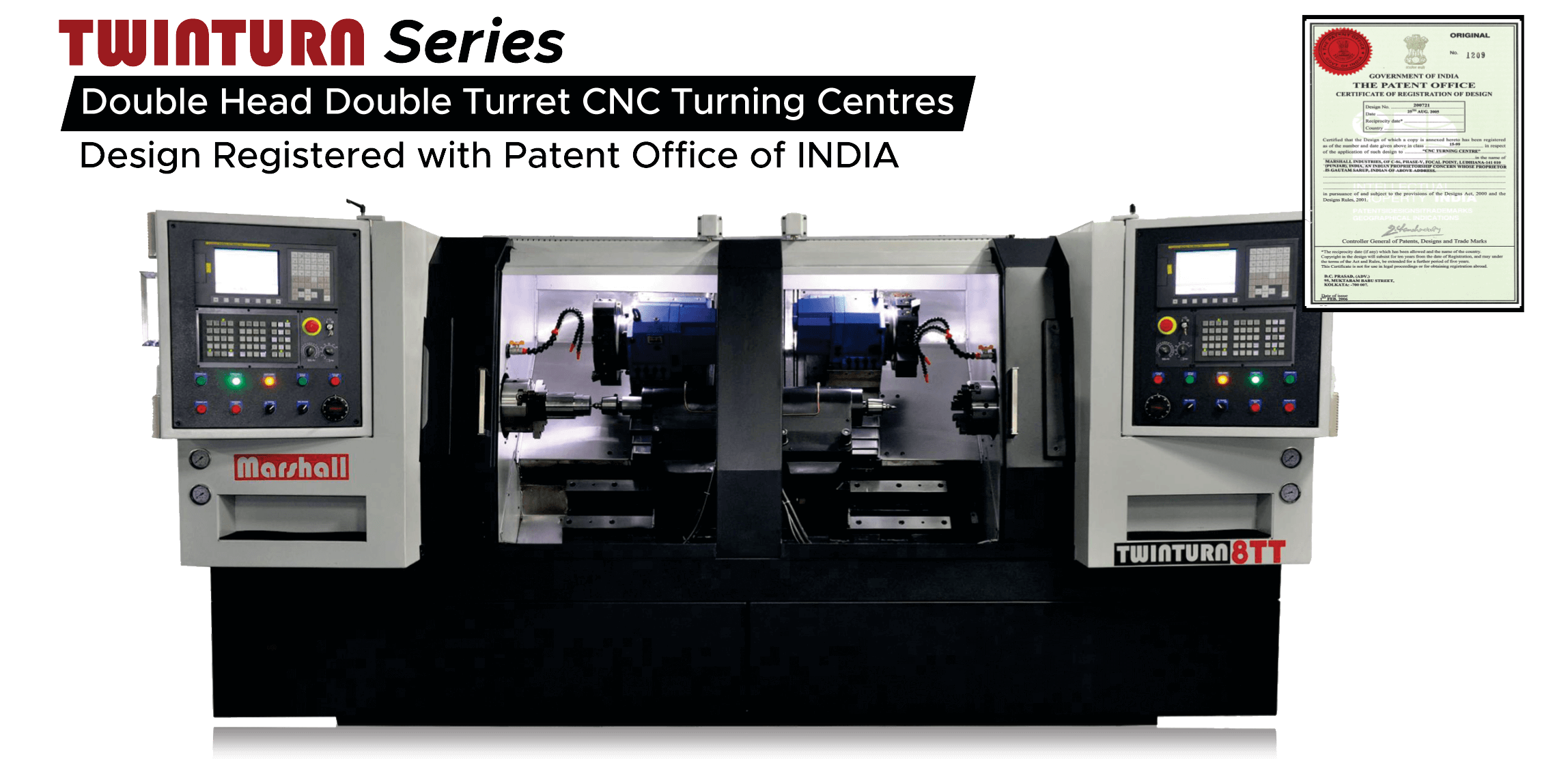

TWINTURN T Series

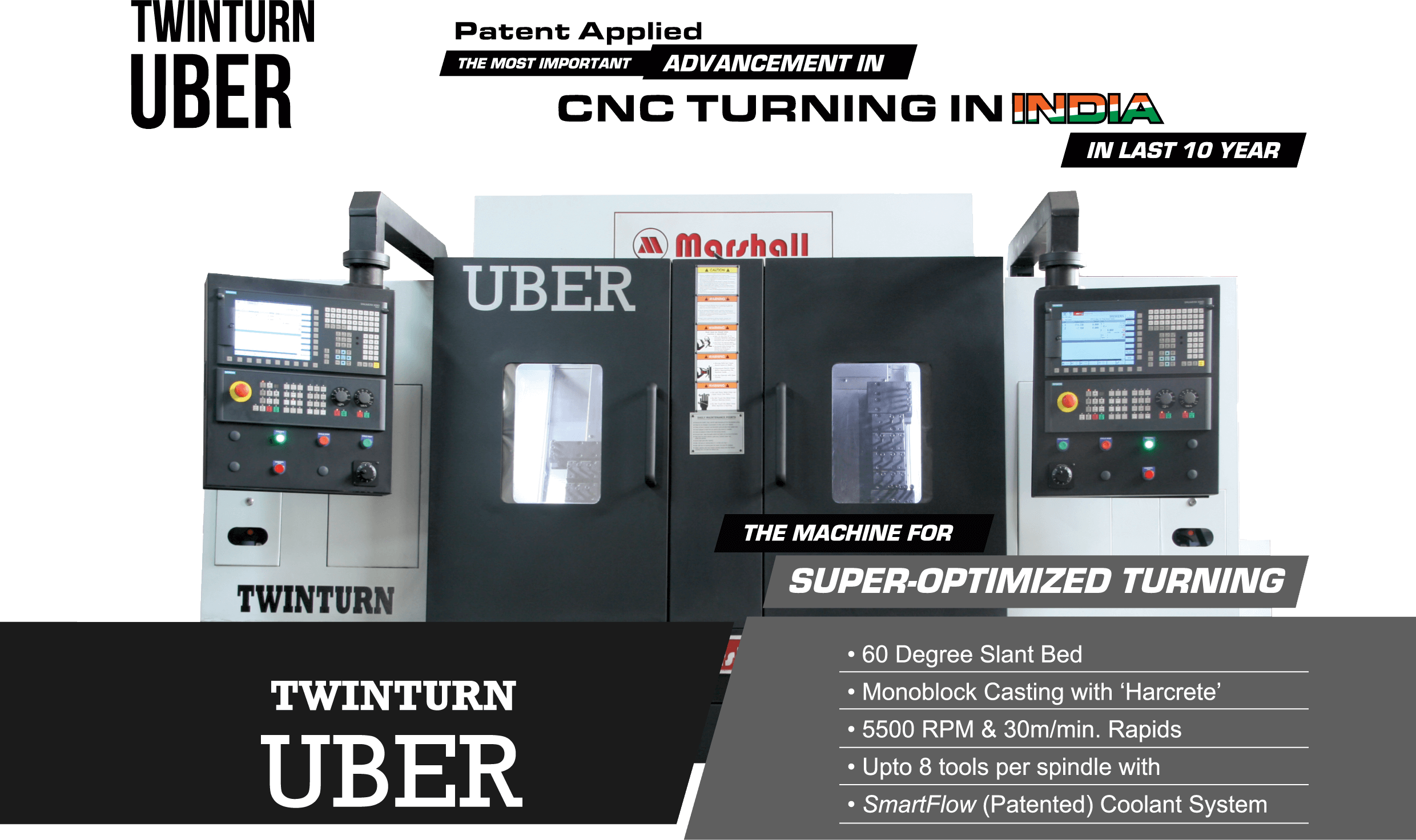

TWINTURN UBER

RIGIDITY of Bed & Base

RIGIDITY of Head & Spindle Assembly

RIGIDITY of Tailstock

RIGIDITY of LM Guideways

This machine is being used to Hard Turn (O.D.) and soft turn (Ends) of Chilled Rolls with weight of 2500 Kg.

Our design, manufacturing processes & selection of inest machine elements from the best manufacturers in the world ensure the following:

• RIGIDITY of Bed & Base

• RIGIDITY of Head & Spindle Assembly

• RIGIDITY of Tailstock

• RIGIDITY of LM Guideways

This Attribute of RIGIDITY is present in even our smallest models because RIGIDITY is vital for:

Productivity | Accuracy | Surface finish | Tool Life

Specifications

Model | SL-20 | SL-25 | SL-30 | SL-40 | SL-50 |

CAPACITY |

|

|

|

|

|

Swing Over Bed (mm) | 630 | 750 | 800 | 850 | 1000 |

Maximum Turning Dia. (mm) | 350 | 400 | 500 | 650 | 800 |

Maximum Turning Length (mm) | 500/700/ | 700/1000/1500 | 700/1000/1500 | 700/1000/1500 | 700/1000/1500 |

MAIN SPINDLE | 1000/1500 | /2000 | /2000/2500/3000 | /2000/2500/3000 | /2000/3000 |

Spindle Nose (Standard) | A2-8 | A2-8 | A2-11 | A2-15 | A2-15 |

Front Bearing Bore (mm) | 110 | 110 | 150 | 180 | 240 |

Maximum Bar Capacity (Std.) (mm) | 55/64 | 55/64 | 75/90 | 90/110 | 160 |

SPINDLE DRIVE |

|

|

|

|

|

Spindle Motor rated power (KW) Fanuc | 11/15 12/16 | 11/15 12/16 | 15/18.5 | 18.5/22 (or as req.) | 22/26 (or as req.) |

Inf. Variable speed range (rpm) | 50-3000 | 50-2800 | 50-2000 | 20-1200 | 20-1200 |

RAPID TRAVERSE |

|

|

|

|

|

STANDARD |

|

|

|

|

|

X-axis (m/min.) | 24 | 20 | 20 | 20 | 15 |

Z-axis (m/min.) | 24 | 20 | 20 | 20 | 15 |

TAILSTOCK |

|

|

|

|

|

Taper in Quill (mm) | MT-5 | MT-5 | MT-6 | MT-6 | MT-6 |

Adjustable Thrust (Max.) | 600 | 600 | 750 | 1000 | 1000 |

TOOL TURRET |

|

|

|

|

|

No. of Stations (Std.) | 8 | 8 | 8/12 | 12 | 12 |

Tool Cross Section (mm) | 25x25 | 32x32 | 32x32 | 32x32 | 32x32 |

Max. Boring Bar Dia. | 40 | 50 | 50 | 50 | 50 |

POSITIONING REPEATABILITY |

|

|

|

|

|

X-axis | ± 1.5 Microns | ± 1.5 Microns | ± 1.5 Microns | ± 2 Microns | ± 2 Microns |

Z-axis | ± 2 Microns | ± 2 Microns | ± 2 Microns | ± 3 Microns | ± 3 Microns |

CNC Controls: SIEMENS / FANUC 0iTF |

|

|

|

|

|

Weight (approx.) (Kg) 6500/7500/ | 8000/9000/ | 8500/9500/ | 8500/9500/ | 9000/10000/ | |

8000/9000 | 10500/12500 | 11000/12500/ | 11500/13000/ | 11500/13500/ | |

|

| 13500/14500 | 14000/15500 | 14500/16000 | |

Model | SL-11(D) | SL-12(D)XF | DS 450 | SL-14 (D) | SL-16 (D) XF | |

CAPACITY |

|

|

|

|

| |

Swing Over Bed (mm) | 310 | 350 | 400 | 450 | 450 | |

Maximum Turning Dia. (mm) | 135 | 210 | 250 | 260 | 350 | |

Maximum Turning Length (mm) | 100 | 125 | 125 | 150 | 200 | |

Stroke (mm) | 300 | 300 | 400 | 600 | 900 | |

MAIN SPINDLE |

|

|

|

|

| |

Spindle Nose (Standard) | A2-4 | A2-5 | A2-5/A2-6 | A2-6 | A2-8 | |

Front Bearing Bore (mm) | 80 | 85 | 85/100 | 100 | 110 | |

Maximum Bar Capacity (Std.) (mm) | 32 | 38 | 38-45 | 45 | 55 | |

(Optional) (mm) | 32 | 42 | 42-52 | 52 | 64 | |

SPINDLE DRIVE |

|

|

|

|

| |

Spindle Motor rated power (KW) Fanuc | 5.5/7.5 | 7.5/11 | 7.5/11 | 7.5/11 | 11/15 | |

Siemens |

| 9/12 | 9/12 | 9/12 | 12/16 | |

Inf. Variable speed range (rpm) | 100-4500 | 100-4000 | 100-4000 | 100-3500 | 50-2800 | |

RAPID TRAVERSE STANDARD |

|

|

|

|

| |

X-axis (m/min.) | 24 | 24 | 24 | 20 | 20 | |

Z-axis (m/min.) | 24 | 24 | 24 | 20 | 20 | |

POSITIONING REPEATABILITY |

|

|

|

|

| |

X-axis | ± 1.5 Microns | ± 1.5 Microns | ± 1.5 Microns | ± 1.5 Microns | ± 1.5 Microns | |

Z-axis | ± 2 Microns | ± 2 Microns | ± 2 Microns | ± 2 Microns | ± 2 Microns | |

CNC Controls: SIEMENS / FANUC 0iTF |

|

|

|

|

|

|

Weight (approx.) (Kg) | 4000 | 4500 | 5000 | 6000 | 7000 | |

| Model | TWINTURN | TWINTURN | TWINTURN | TWINTURN | TWINTURN |

| 6T (90) | 6TT | 8T/8TT | 12TT | XL | |

| CAPACITY | |||||

| Swing Over Bed (mm) | 400 | 400 | 450 | 520 | 750 |

| Maximum Turning Dia. (mm) | 250 | 250 | 320 | 360 | 500 |

| Maximum Turning Length (mm) | 150 | 340 | 140/330 | 325 | 350 |

| with Tailstock | |||||

| MAIN SPINDLE | |||||

| Spindle Nose (Standard) | A2-5 | A2-5 | A2-6 | A2-8 | A2-11 |

| Front Bearing Bore (mm) | 85 | 85 | 100 | 110 | 150 |

| Maximum Bar Capacity (Std.) (mm) | 38 | 38 | 45 | 55 | 75 |

| (Optional) (mm) | 42 | 42 | 52 | 64 | 90 |

| SPINDLE DRIVE | |||||

| Spindle Motor rated power (KW) Fanuc | 7.5/11 | 7.5/11 | 7.5/11 | 43784 | 15/18.5 |

| Siemens | 43720 | 43720 | 43720 | 43815 | 16/21 |

| Inf. Variable speed range (rpm) | 100-4000 | 100-4000 | 100-3200 | 50-2800 | 30-1800 |

| RAPID TRAVERSE | |||||

| STANDARD | |||||

| X-axis (m/min.) | 24 | 24 | 24 | 20 | 20 |

| Z-axis (m/min.) | 24 | 24 | 24 | 20 | 20 |

| TOOL TURRET | |||||

| No. of Stations (Std.) | 8 | 8 | 8 | 8 | 12 |

| Tool Cross Section | 25x25 | 25x25 | 25x25 | 25x25 | 32X32 |

| Max. Boring Bar Dia. | 40 | 40 | 40 | 40 | 50 |

| POSITIONING REPEATABILITY | |||||

| X-axis | ± 1.5 Microns | ± 1.5 Microns | ± 1.5 Microns | ± 1.5 Microns | ± 2 Microns |

| Z-axis | ± 2 Microns | ± 2 Microns | ± 2 Microns | ± 2 Microns | ± 3 Microns |

| CNC Controls: SIEMENS / FANUC 0iTF | |||||

| Weight (approx.) (Kg) | 6500 | 6800 | 7000 | 8000 | 11000 |

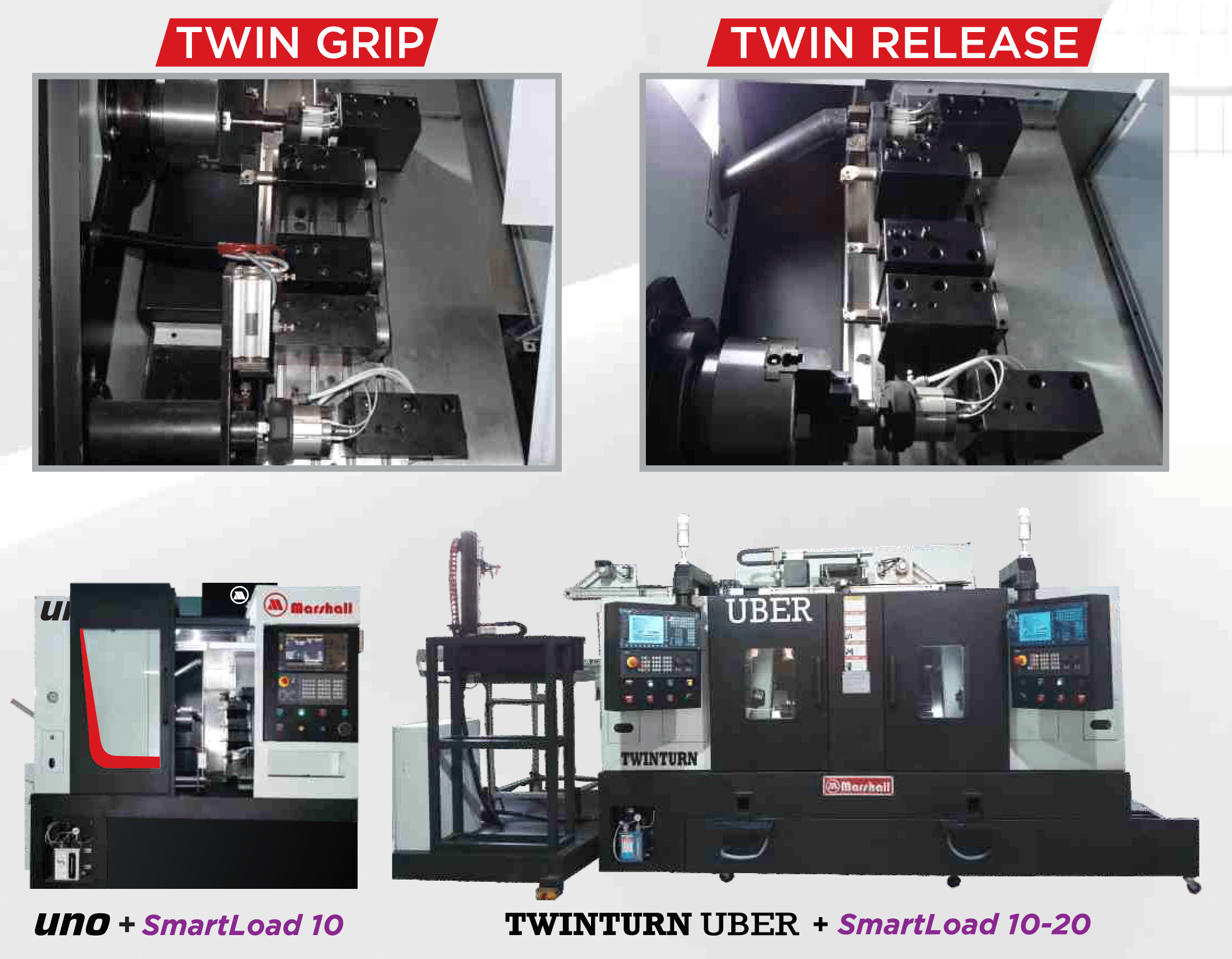

AFFORDABLE AUTOMATION

UNO + SMARTLOAD 10

ROBOTURN Series

Five Advantages of SmartLoad Technology

RELIABLE Min. No. of Moving Parts

COMPACT Smallest Footprint

SAFE Mechanism inside the machine. No risk to humans

FAST 8-10 Sec. Load/unload time

ECONOMICAL 50% the cost of Gantry or Robot based Automation.

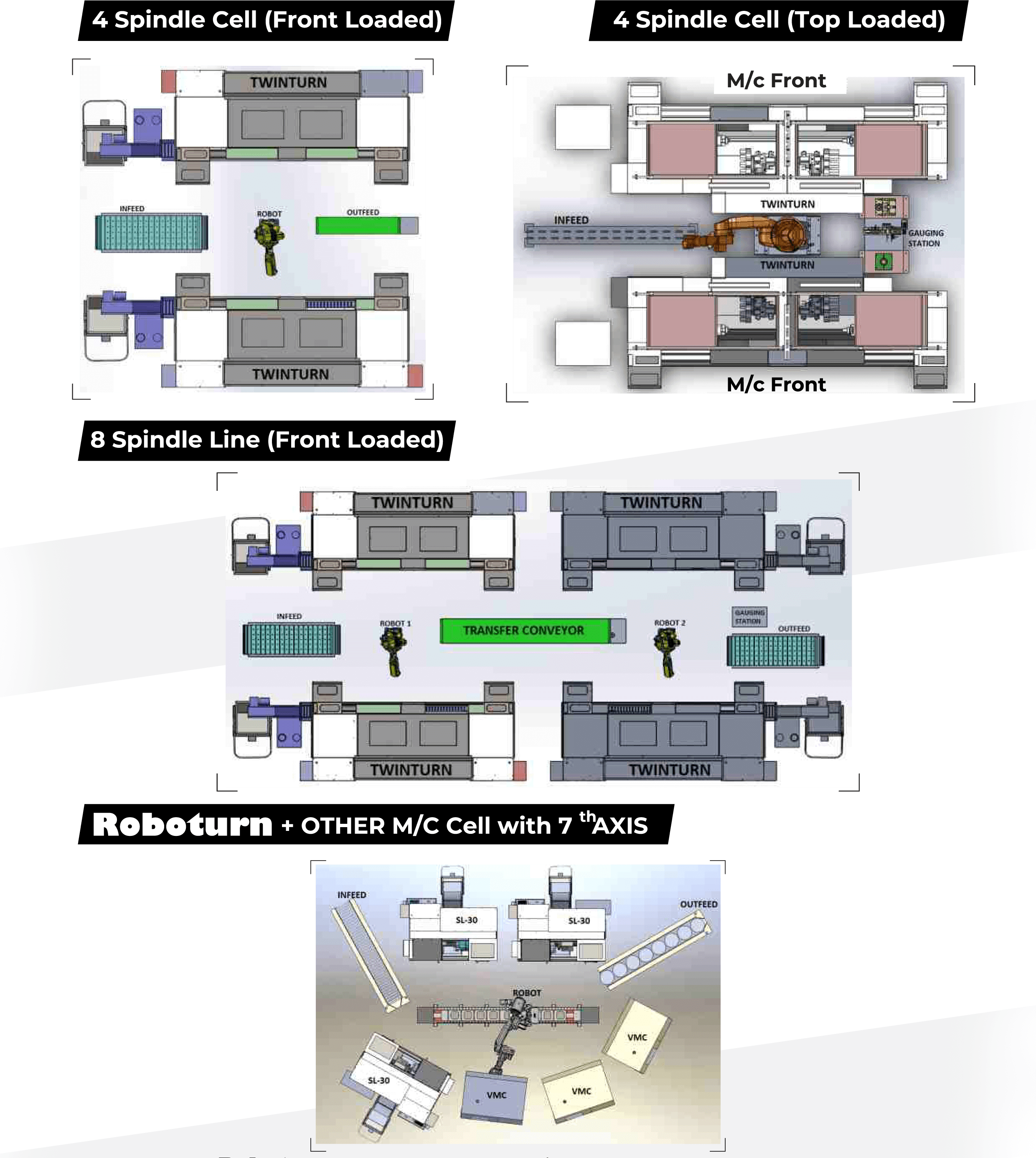

Roboturn Cells & Lines Concepts

SMARTFAC: INDUSTRY 4.0 REIMAGINED !

'Smart' Industry 4.0 Tech for Closed Loop Operation of Machine Shops

The Smart Solution for ‘3 Pain Points’ of every Machine Shop

#1 Decline in Aptitude & Attitude of Skilled Operators

#2 Exponential Jump in Quality demanded by Customers.

#3 Poor Productivity (OEE) of machines, unplanned stoppages & frequent breakdowns